Castings for Lighting Industry in Die Casting Foundries

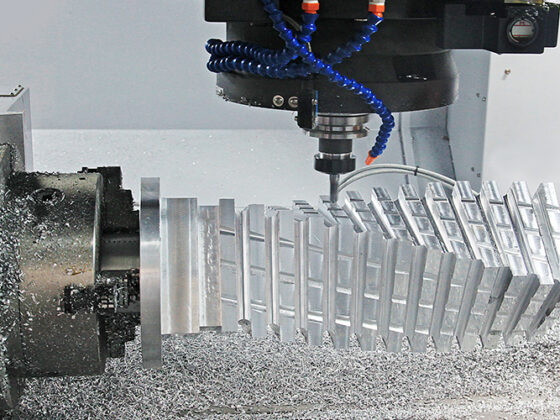

In the modern lighting industry, aluminum pressure die casting plays a vital role in producing high-quality lighting casting parts that illuminate our lives and many parts used in this sector. As a leading foundry company…